Accelerate Automotive Innovation to Top Speed (Part 4 of 6)

Innovation has become an exercise of advancing embedded systems to stay ahead in the highly competitive automotive industry. While opening up great new opportunities, integration of software into mechatronics also presents unprecedented challenges to development teams.

This series of articles presents an in-depth look at the challenges facing the rapid advance of mechatronics in the automotive industry, and discusses business best practices gleaned from our customers successfully using Polarion solutions to meet the challenges. Part 1 was an overview of the challenges. Part 2 looked at effective real-time collaboration strategies. Part 3 discussed Proactive Protection of Quality and Functional Safety. This fourth article continues the discussion of strategies.

Rapid Response to Defects After Market Introduction

As valuable as preventative measures are, we all know the first law of software development: there is no such thing as bug-free software. In the automotive industry, it’s a variation of the “last mile” challenge, described as the “last .001%” problem. In other words, debugging the first 99.99% of software defects is part of standard business for any manufacturer. But beyond that, it gets really difficult to catch problems because software has grown so complex.

Source: US Department of Transportation

Variations of real-world test conditions can be near-infinite, such as the differences in temperature, speed, acceleration, and torque when combined with specific software-driven functionality. In turn, it has become cost prohibitive to test all software and systems combinations across all operating conditions.

To continuously manage against risks, hazards, and cost has become a giant probability exercise, managed over thousands of dependent and independent variables.

Toyota’s recent filing with the NHTSA (National Highway Traffic Safety Administration) sheds more light on this new reality by revealing three important findings:

- The recall stemmed from transistors that at high operating temperatures could potentially shut down the car’s hybrid system. In other words, the issues surfaced at the nexus of hardware, software and real-world operating conditions.

- The recall impacted a single model year produced over a four-year period, from 2010 to 2014. This means it was small enough to persist undetected through multiple vehicle validation cycles.

- To date, the defect has caused no injuries or accident, and the recall has been solely preemptive and voluntary.

This presents a good example of the complexities the automotive industry is facing, causing those record-busting recalls, which have become the new norm rather than the exception. Almost all automotive manufacturers have included recalls into their standard operating procedures, both voluntarily as well as in response to regulatory directive and legal demands. Lately, these recalls are more and more often due to some supplier’s error that didn’t become apparent until after the car was introduced into the marketplace.

There is yet another kind of recall that can be just as costly. Car manufacturers often issue “silent” recalls that we only learn about when we bring our cars to a dealer for service. The cost of developing a resolution for the issue, training dealer employees to repair the issue, the effort to deliver the parts and to apply the software patches to thousands of dealers across the globe can easily eliminate most profits from the car model that is affected by a silent recall.

Source: NHTSA

While total numbers of recalls vary from year to year, they have climbed steadily in each of the past decades, according to analysis of nearly a half century’s worth of data from the National Highway Traffic Safety Administration.

For 2014, the Society of Automotive Analyst (SAA) Annual Warranty and Recall Report lists the following as the most influential forces driving the record-breaking recalls the automotive industry has been experiencing:

- Increase in New Vehicles: 37 new vehicles to be introduced in 2014 stresses ecosystems

- Increase in Sales Volume: 16.3 M expected for 2014 causing production and capacity constraints

- Cost Cutting Efforts to improve short term profitability expected to lead to a deterioration of product quality

- Technological Innovation Complexity results in software glitches that drive “hard failures”

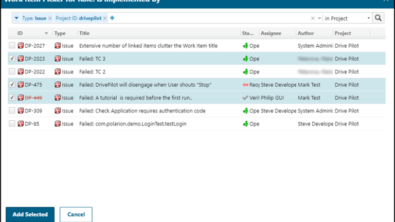

The good news is that Polarion has a powerful answer for this reactive scenario as well. The same linking and traceability capabilities that enable teams to collaborate seamlessly and ensure smooth compliance with automotive standards before vehicles get introduced to consumers, also helps them track down the source of any issue that surfaces after the fact. The common practice is that engineers get called off their projects to frantically search for root causes. Sometimes defects have such a negative impact that management decides to shut down production lines until defects are found and fixed. To make matters worse, modern organizations tend to use an amalgam of testing tools, making it harder to get to the bottom of issues and prolonging costly disruptions. As a result, affected OEMs and their suppliers are facing billions of dollars in damage any time a serious defect surfaces after market introduction.

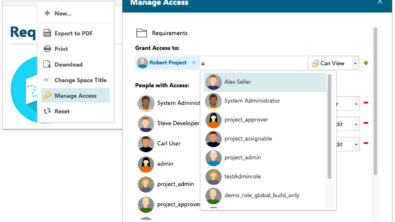

Polarion addresses these challenges head-on thanks to its role as a central hub where all testing routines are orchestrated. This encompasses unified defect management, where every issue is tracked as a Work Item in Polarion regardless of the testing tool that identified it, including details about the test routine that was performed, the results that were found, the remedy that was assigned to which resource, etc. As a result, a comprehensive and fully linked audit trail allows teams to trace market-facing defects with rapid speed all the way back to the source code regardless of the number of testing tools used in an organization. Furthermore, requirements related to the case are directly accessible as well, completing the picture.

Next time…

In the next installment, Part 5 of this series, we’ll continue looking at strategies: Smooth Compliance with Automotive Standards.

“Thanks to Polarion, we can rely on a single platform to collect our data, exchange documents, collaborate, keep traceability, and control our workflow. With Polarion, we can not only measure our productivity but also improve productivity in our projects. And we can keep track of this!”

— Andreas Deuter, PHOENIX CONTACT Electronics